2400 km Vilnius streets detail asphalt investigation

We have been awarded with a contract in public tender with a big and challenging project. It can be a very good test of our fast new processes adaptation abilities.

This project requires to do a very detail road surface investigation and the data will be used to prioritise roads for more efficient and cost-effective repair works. This is very important for a good road management and we congratulate Vilnius city municipality and Grinda, UAB for taking care of Vilnius streets in worldwide practice. It shows Vilnius’ level of innovations, adoption and care of wise public money care.

During this project we will investigate around 2400km of Vilnius street lanes. We will prepare a dataset of information all over Vilnius streets. It will be separated into 10m sections and we will have average rutting, IRI, percentage of cracks and potholes.

Rutting is a pushed down asphalt under the wheels. It is one of the most common issues with asphalt due to intensive traffic. Water stays in the rutting area during the rain and the safety of streets decreases drastically. It Is very important to have detailed information and prevent asphalt damages with cheaper repair works.

IRI (International roughness index) is one of the most important parameters for road safety and good car abilities to stop. This index shows a very detailed road profile (in this project scope – two profiles by each vehicle wheel). It allows identifying changes of profile and it is the most common parameter for more detailed road investigation.

Cracks show asphalt damages and before it becomes a pothole – early investigation of cracking can prevent roads from expensive re-surfacing or base repair. This information of cracking and damages of Vilnius streets will allow the municipality to use public money more efficiently for road repair works.

There are so many different types of cracking:

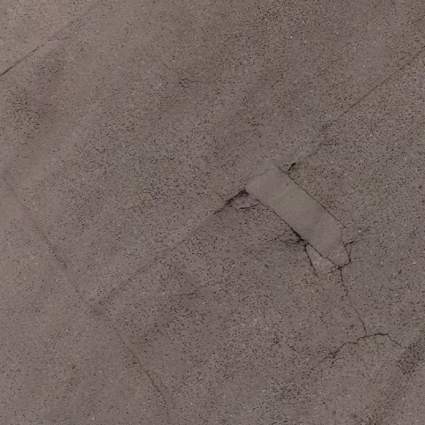

- Alligator cracking. Alligator cracking is a load associated with structural failure. The failure can be due to weakness in the surface, base or sub grade; a surface or base that is too thin; poor drainage or the combination of all three. It often starts in the wheel path as longitudinal cracking and ends up as alligator cracking after severe distress.

- Block cracking. Block cracks look like large interconnected rectangles (roughly). Block cracking is not load-associated, but generally caused by shrinkage of the asphalt pavement due to an inability of the asphalt binder to expand and contract with temperature cycles. This can be because the mix was mixed and placed too dry; Fine aggregate mix with low penetration asphalt & absorptive aggregates; poor choice of asphalt binder in the mix design; or aging dried out asphalt.

- Longitudinal cracking. Longitudinal cracking are cracks that are parallel to the pavement’s centerline or lay down direction. These can be a result of both pavement fatigue, reflective cracking, and/or poor joint construction. Joints are generally the least dense areas of a pavement.

- Transverse cracking. Transverse cracks are single cracks perpendicular to the pavement’s centerline or lay down direction. Transverse cracks can be caused by reflective cracks from an underlying layer, daily temperature cycles, and poor construction due to improper operation of the paver.

- Edge cracking. Edge Cracks travel along the inside edge of a pavement surface within 30-50 cm. The most common cause for this type of crack is poor drainage conditions and lack of support at the pavement edge. As a result underlying base materials settle and become weakened. Heavy vegetation along the pavement edge and heavy traffic can also be the instigator of edge cracking.

- Joint Reflection Cracks. These are cracks in a flexible pavement overlay of a rigid pavement (i.e., asphalt over concrete). They occur directly over the underlying rigid pavement joints. Joint reflection cracking does not include reflection cracks that occur away from an underlying joint or from any other type of base (e.g., cement or lime stabilized).

- Slippage cracks. Slippage cracks are crescent-shaped cracks or tears in the surface layer(s) of asphalt where the new material has slipped over the underlying course. This problem is caused by a lack of bonding between layers. This is often because a tack coat was not used to develop a bond between the asphalt layers or because a prime coat was not used to bond the asphalt to the underlying stone base course. The lack of bond can be also caused by dirt, oil, or other contaminants preventing adhesion between the layers.

- Potholes. Small, bowl-shaped depressions in the pavement surface that penetrate all the way through the asphalt layer down to the base course. They generally have sharp edges and vertical sides near the top of the hole. Potholes are the result of moisture infiltration and usually the end result of untreated alligator cracking. As alligator cracking becomes severe, the interconnected cracks create small chunks of pavement, which can be dislodged as vehicles drive over them. The remaining hole after the pavement chunk is dislodged is called a pothole.

- Depressions. Depressions are localized pavement surface areas with slightly lower elevations than the surrounding pavement. Depressions are very noticeable after a rain when they fill with water.

- Rutting. Ruts in asphalt pavements are channelized depressions in the wheel-tracks. Rutting results from consolidation or lateral movement of any of the pavement layers or the subgrade under traffic. It is caused by insufficient pavement thickness; lack of compaction of the asphalt, stone base or soil; weak asphalt mixes; or moisture infiltration.

- Shoving. Shoving is the formation of ripples across a pavement. This characteristic shape is why this type of distress is sometimes called wash-boarding. Shoving occurs at locations having severe horizontal stresses, such as intersections. It is typically caused by: excess asphalt; too much fine aggregate; rounded aggregate; too soft an asphalt; or a weak granular base.

- Upheaval. Upheaval is a localized upward movement in a pavement due to swelling of the subgrade. This can be due to expansive soils that swell due to moisture or frost heave (ice under the pavement).

- Raveling (very porous asphalt). Raveling is the on-going separation of aggregate particles in a pavement from the surface downward or from the edges inward. Usually, the fine aggregate wears away first and then leaves little “pock marks” on the pavement surface. As the erosion continues, larger and larger particles are broken free and the pavement soon has the rough and jagged appearance typical of surface erosion. There are many reasons why raveling can occur, but one common cause is placing asphalt too late in the season. This is because the mixture usually lacks warm weather traffic which reduces pavement surface voids, further densification, and kneading of the asphalt mat.